Antenna Building – Sourcing The Right Aluminium Stock

So, you’ve got a great new antenna design and all you need do is source the aluminium stock. Pretty simple I hear you say – but not so fast as you may end up with a heap of scrap metal and with some low-grade stock that won’t last an hour in a good breeze. Read on here and we’ll guide you through and around all the potential pitfalls based on my own purchasing experiences.

So, let’s begin with a little background info. We’re not going to dig too deep as it can get quite technical but I’ll try to give you the top-level rundown. Aluminium comes in a variety of different grades [or ‘Series‘ of alloys]. The numbering of each alloy uses a 4-digit reference, for example 1xxx, 2xxx, etc. up to 8xxx. The first numeral indicates the principle element that has been added to the aluminium which affects many things including its workability and of course tensile strength. For the technically inclined – here’s a reference which explains it in more details.

In addition to the basic metals used to ‘construct’ the alloy, the stock can be subject to various treatments which makes the alloy harder and stronger. These treatments are called ‘tempers‘ and use a ‘T’ prefix, followed by a number – ‘T6‘ for example. Some alloys lend themselves well to the use of heat to achieve strength. Others are strain hardenable only.

The 2xxx, 6xxx, and 7xxx series aluminium alloys are heat treatable and the 4xxx series consist of both heat treatable and non-heat treatable alloys. The most commonly sold aluminium alloys in UK stockists are the 6xxx series. The 6xxx series has additional magnesium and silicon elements included in the ‘mix’ which adds strength over and above say the virgin 1xxx stock which, in its basic form, is 99% pure aluminium and is very soft indeed. So, let’s see what’s on the table for the homebrew builder.

6060-T4 or 6060-T6

Well, let’s get this one out of the way first. This is one to avoid unless you absolutely have no other choice – but don’t expect it last. The T6 temper is the stronger of the two but at only 214Mpa [‘Megapascals‘ – the units used to measure the alloy’s tensile strength], it’s far too soft to construct reliable long lasting antenna arrays [especially lower frequency ones]. Unfortunately, this is a very common stock that’s sold by the bucket load in mainland Europe. The chances are very high that if you purchase from a European manufacturer – they’ll be using 6060 stock. It’s freely available, relatively cheap but not very strong and bends very easily. Some EU stockists even sell the 6060-T4 temper which is even softer at 160Mpa. On the plus side it’s extremely easy to work with and weld. It’s also started to appear in UK stockists recently.

Our advice – steer clear if you want to avoid trouble

6063-T6

The 6063-T6 is a classed as a ‘General Purpose Alloy‘ and is commonly sold in many UK outlets. It’s actually [not] that bad and could be used where a stronger alloy is not available. For tubes, I’ll generally try to steer away from this but it’s quite a bit stronger [241Mpa] than the softer EU stock. You could mix a single 6063-T6 tube in amongst 6082-T6 tubes without degrading the overall strength too much. For square box section booms, we found 6063-T6 is fine to use. It’s extremely easy to work with and weld. It’s also cheaper than the higher grade 6xxx alloys.

Our advice – only use a single section tube where a stronger alloy is not available.

6082-T6

This is the UK’s equivalent of the US 6061-T6 ‘Aircraft Quality‘ alloy. This is classed as an ‘Industrial Alloy‘ for use in construction. As such, it’s strength is 310Mpa and uses include extrusions where strength is the prime factor. 6082-T6 is freely available from most UK stockists although it’s more expensive than 6063-T6 as it’s a premium product. It’s not so easy to work with and trying to ‘cold-form‘ it [may] cause it to crack although it does weld well. 6082-T6 formed the basis of most Vortex Antenna arrays although we also had access to additional stronger alloys from time to time [see below].

Our advice – recommended

6061-T6

This is the commercial grade US ‘Aircraft Alloy‘ that’s on par with the UK’s 6082-T6. They are often compared with each other. Used frequently in commercial environments, 6061 can be found in abundance in the US. The chances are, if you purchase an antenna from the USA, it will be 6061-T6 or 6061-T651 [they are very similar]. It’s great stock and built to last.

Our advice – recommended

AA6082-T6

From here we start to drift into the specialist metal arena. AA6082-T6 is Aalco’s UK’s equivalent of the 6082-T6 alloy. This is classed as an ‘Industrial Alloy‘ for use in construction. It’s actually like 6082-T6 on steroids with a strength of 340Mpa and uses include extrusions where strength is going to be the prime factor. AA6082-T6 is not freely available from UK stockists and is normally only available when ordered directly from Aalco. Vortex has used various AA6082-T6 tubes from 2013-2018 when stock allowed. Saying that, Smiths Metals have been known to use Aalco in the past [that’s where we got the first Vortex stock from] and we found quite a few Aalco manufactured tubes back there in 2013. Worth using if you can find some.

Our advice – highly recommended

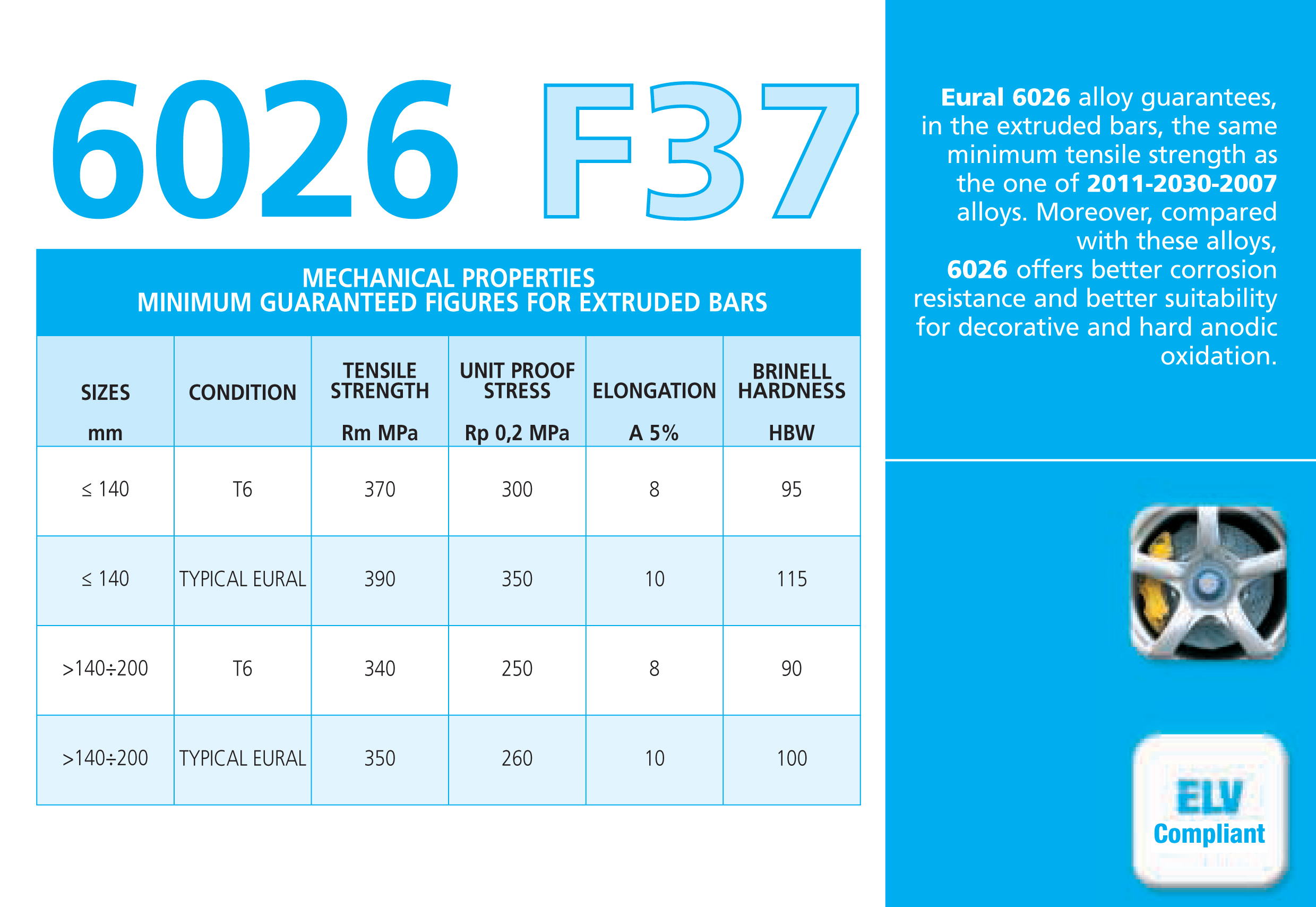

6026-F37 T6

Back in 2015, I managed to secure quite a lot of this ‘new’ super strong European stock. 6026-F37 T6 tubing seems to have been first produced by Eural in Italy. At 390Mpa in T6 and over 400 in T9 temper it’s extremely strong and more resembles steel than aluminium. It’s not cheap either, being quite a bit more expensive than 6082-T6. It’s not available as tubes in the UK unless ordered especially from a mill, although Aalco produce bars using 6026-T9 stock. Current EU antenna manufactures are also highly unlikely to use this. Just in case you thought your new EU antenna may be made from this 🙁 Mainly used in very high-quality construction projects where super-strength is the prime factor and cost is not a real issue when deciding.

Our advice – highly recommended [if you can find any]

Metric vs Imperial

So – which do you use? In the UK, the majority of aluminium produced is imperial although the amount of metric tubes has increased dramatically over the last 5 years which is good news. I use a mix of both to achieve a nice telescoping of the tubes without too much free play.

With All The Theory Done – Where Can I Buy My Stock?

Taking the speciality alloys out of the mix, we have three great suppliers worthy of a mention.

Simmal [North West]

When you first visit the Simmal website, it looks to be trade facing – but that’s not the case. Tube, box, bar and extrusion can all be ordered online by either the trader or consumer alike.

Apart from offering full lengths, the web app also allows you to purchase part lengths. If for example you only need a 1m section of a 5m length, you can put the required length into website box and the form will charge you only for what you want. Part lengths however, are a little bit more expensive per meter than full lengths – but not by much, so worth considering.

Simmal are fast and will often ship the same or next day for a flat £16.99 shipping cost across the UK, regardless of whether you ship 5 or 50kg. It’s good value for larger orders. Price wise they are one of the best in the UK. Some equivalents at other outlets can be more expensive.

Aluminium Warehouse [Herts]

AW continue to be a leading consumer supplier in the UK. They have a good range and are generally priced fairly well. Saying that, Simmal [above] frequently better them on price. Currently Aluminium Warehouse are the only outlet stocking metric 12mm tubes as 1/2 inch tubes [12.7mm] won’t fit inside the 5/16th’s stock – so the chances are, you’ll be ordering at least something from them. The website is modern, slick and well designed. For info, you can’t order part lengths although AW do offer a cutting service if you purchase a full length. Delivery charges are a one-off at £15 – again not limited to weight. AW can however, be slow to ship.

LA Metals [West Mids]

The first major order we did was from LA. It’s a nice setup and the Joe and the team are great to deal with. They used to be able to get metric size tubes which helped a lot when I first started out. They are more ‘Trade’ facing but are always happy to help the consumer out. Unfortunately, you can’t order stock directly from the website but they do offer additional services such as fabrication, powder coating and anodising. Check out LA Metals online here.

Round tubes that telescope into each other

Here’s a list of tube sizes that are great for making the elements of antennas.

- Metric: 30mm x 2mm wall [Available at A/W or Simmal]

- Metric: 25mm x 2mm wall [Available at A/W or Simmal]

- Metric: 20mm x 1.5mm wall [Available only at Simmal]

- Imperial: 5/8ths [15.875mm] x 16 gauge [1.626mm wall] [Available at A/Warehouse or Simmal]

- Or as a metric alternative: 16mm x 1.5mm wall [Available at Simmal – max 3.2m lengths]

- Metric: 12mm x 2mm wall [Available only at A/Warehouse]

Square tubes that telescope into each other

Here’s a list of tube sizes that are great for making boom sections.

- Metric: 80mm x 80mm x 4mm wall [Available only at Simmal]

- Metric: 70mm x 70mm x 4mm wall [Available only at Simmal]

- Metric: 60mm x 60mm x 4mm wall [Available at A/W or Simmal]

- Imperial: 2 inch [50.8mm] x 2 inch [50.8mm] x 10 gauge wall [3.25mm wall] Available at A/W or Simmal]

- Metric: 40mm x 40mm x 3mm wall [Available only at A/W]

- Imperial: 1.25 inch [31.75mm] x 1.25 inch [31.75mm] x 10 gauge wall [3.25mm wall] Available at A/W or Simmal]

Notes to readers: The supplier information on this page and website is based purely on our own experiences and does not in anyway endorse any of the companies mentioned above, although we’ve had a good commercial relationship with all. Advice is based on our own commercial builds since 2008 and what we found ‘worked‘. However, we can’t be held responsible for any user project that doesn’t hit expectations [for whatever reason]. As I am UK based, company references will mainly reflect that the constructor is located in the United Kingdom.